Over the past decade, electric vehicles (EVs) have become more popular among those looking for more environmentally-sound options for personal transportation. However, while the cost has gone lower over time and made EVs more accessible to the masses, there is one key issue that has kept them from entering the mainstream as either an alternative or eventual replacement for fossil fuel-guzzling cars: more stable – and sustainable – batteries.

But researchers at the Georgia Institute of Technology (Georgia Tech) may have stumbled upon a breakthrough that may lead to a safer, more eco-friendly, and longer-lasting fuel source for EVs. Surprisingly, it involves rubber, one of the world’s most commonly used industrial materials.

What We Have Now vs What We Stand to Have

Standard lithium-ion (LiOn) batteries generate power by moving ions with a liquid electrolyte. It works well enough, particularly in smaller devices such as mobile phones and tablets, but it is highly unstable in larger applications. Any form of damage, regardless of severity, can leak into the electrolyte and cause an explosion.

This instability has prompted industry experts to consider more stable alternatives like solid-state batteries made with inorganic ceramics or organic polymer. Unfortunately, solid-state batteries are also difficult to make, expensive to produce, and pose a greater risk to the environment if improperly disposed of.

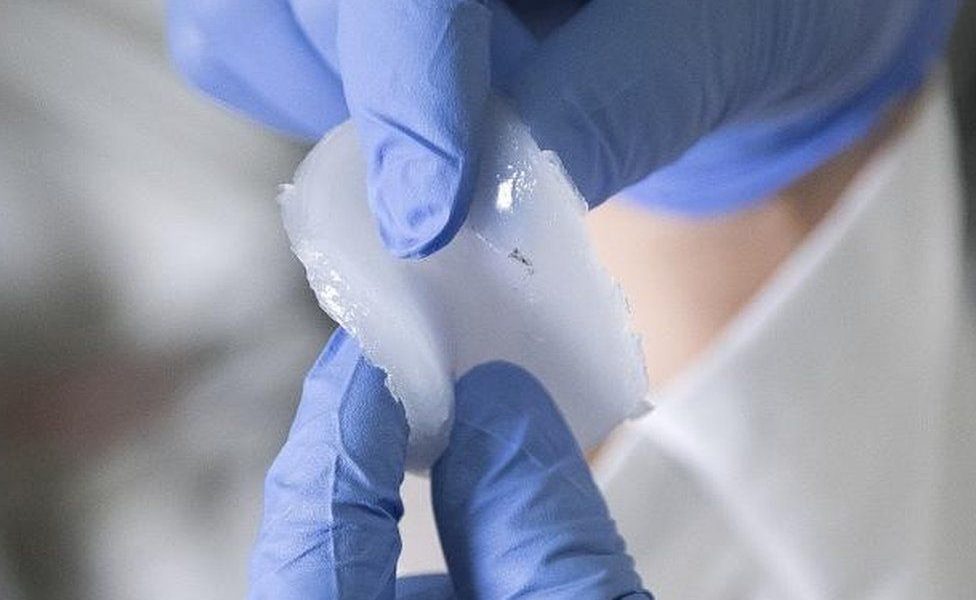

But researchers at Georgia Tech may have hit upon a more sustainable and cost-effective alternative. The discovery of a rubber-derived organic polymer will enable battery makers to form an interconnected three-dimensional structure within the sturdy rubber matrix – a structure that results in higher and more efficient ionic conductivity, along with electrochemical stability, thus preventing the risk of fire and explosions due to leakage.

Georgia Tech’s rubber electrolyte is also easier – and cheaper – to produce. Simple polymerization is induced at low temperatures in order to generate strong, smooth interfaces on the electrode. In doing so, the growth of lithium dendrites is prevented, allowing for the faster movement of ions to ensure more reliable performance from the battery.

The team considered rubber for their solid-state battery as it is more commonly available and its high mechanical properties make it an excellent choice for improving safety and performance. The material’s high ionic conductivity lets more ions move at the same time. In turn, this increases the specific energy and energy density of the batteries in order to improve the mileage of EVs.